Lifting Operations and Lifting Equipment Regulations

(LOLER)

These Regulations came into force on 5 December 1998 and apply to England, Scotland and Wales.

They implement the lifting aspects of Directive 2009/104/EC, on the minimum safety and health requirements for the use of work equipment by workers at work. The non-lifting aspects are implemented by the Provision and Use of Work Equipment Regulations SI 1998/2306 and these Regulations should be read in conjunction with them.

They are supplemented by a number of Approved Codes of Practice (the main one being ACOP L113) and guidance which give more detail on the application of these Regulations.

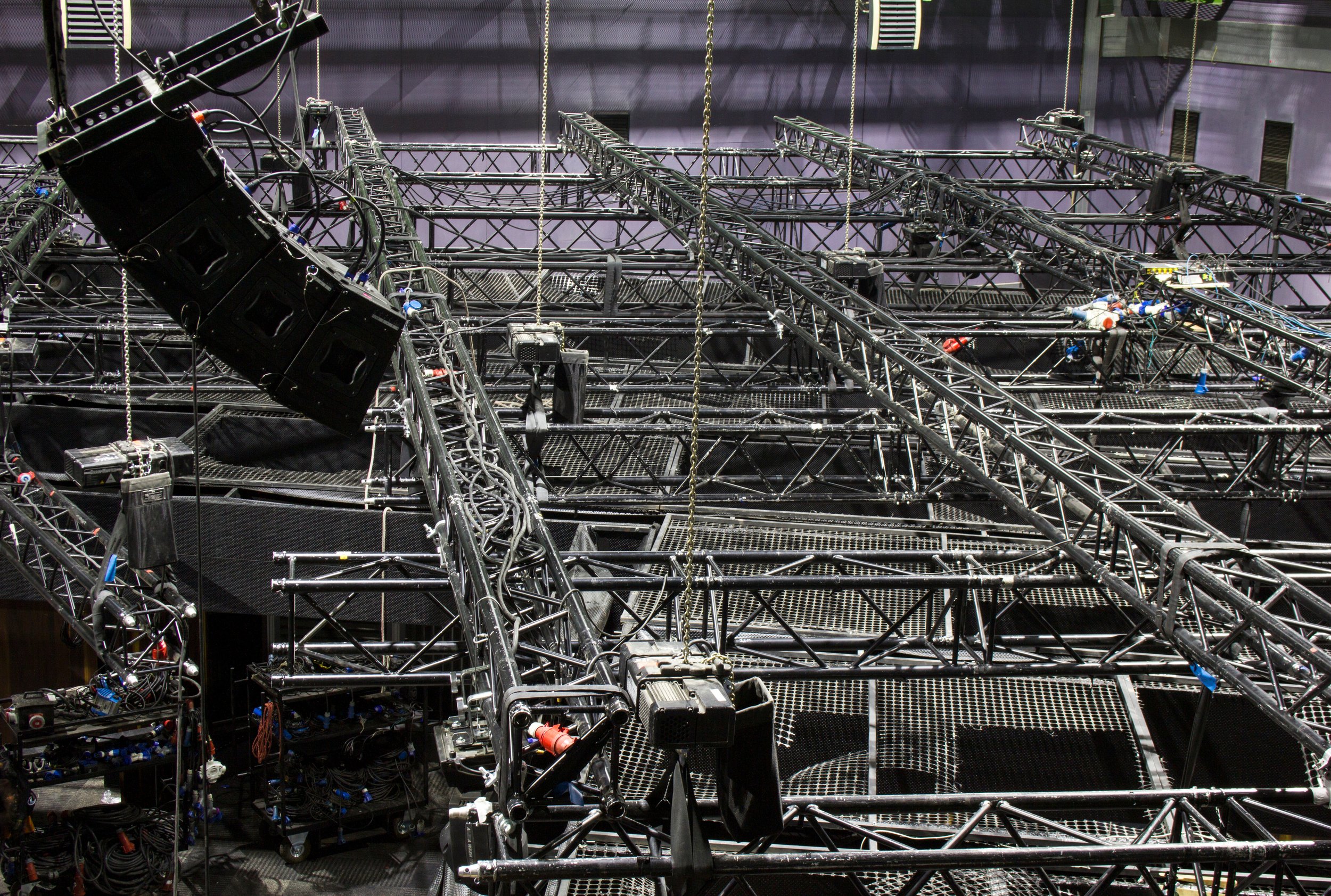

The aim of these Regulations is to make sure that lifting equipment is safe, regardless of its age, condition or origin.

Definitions

In the context of these Regulations:

"Thorough examination" means a thorough examination by a competent person and where appropriate includes testing.

"Examination scheme" means a suitable scheme drawn up by a competent person for such thorough examinations of lifting equipment at such intervals as may be appropriate.

"Work equipment" means any machinery, appliance, apparatus, tool or installation for use at work, whether exclusively or not.

"Lifting equipment" means work equipment for lifting or lowering loads and includes any attachments used for anchoring, fixing or supporting it.

"Lifting operation" means an operation concerned with the lifting or lowering of a load.

"Load" includes a person, material or animal.

"Accessory for lifting" means lifting equipment for attaching loads to machinery for lifting.

Application

These Regulations apply to lifting equipment used at work by employees and self-employed people. They also apply to anyone who has control of any:

lifting equipment;

one at work who uses, supervises or manages the use of lifting equipment;

way in which lifting equipment is used.

These Regulations do not apply to someone who supplies lifting equipment by way of sale, sale agreement, or hire-purchase agreement.

These Regulations do not apply to ship's lifting equipment, whether used on or off the ship. They do apply to activities such as the unloading, fuelling, construction, maintenance and cleaning of ships.

Suitability of lifting equipment

Employers must make sure that lifting equipment is of adequate strength and stability for each load, paying particular attention to any mounting or fixing point. Employers must also make sure that every part of a load and anything attached to it and used in lifting it is of adequate strength.

More detail about the suitability of lifting equipment is given in the ACOP which states that lifting equipment should only be selected if it is made of materials which are suitable for the conditions under which it will be used.

The ACOP also states that where necessary, safe means of access should be provided to any part of the lifting equipment. Where there is an opening in the floor area it should be either adequately covered or fenced. Where there is a risk of someone falling more than 2 metres, suitable edge protection comprising a guard rail, toe board, and mid-rail, or other similar means should be provided.

Any edge protection should be suitable for the purpose and be securely fixed to the lifting equipment. Any gate or barrier in the edge protection should open inwards or in such another way that is safe. Where there is a risk of an object falling from the lifting equipment injuring a person below, suitable edge protection should be provided.

Lifting equipment for lifting people

Employers must make sure that as far as possible lifting equipment for lifting people must prevent:

the crushing, trapping, striking or falling of people from the carrier;

the carrier itself falling;

exposing any trapped person to danger and must enable them to be freed.

Further detail on this is given in the ACOP.

Positioning and installation

Employers must make sure that lifting equipment is positioned or installed so that it reduces the risk of the:

lifting equipment or a load striking a person;

load drifting, falling freely, or being released unintentionally.

Employers must make sure that there are suitable devices to prevent a person falling down a shaft or hoistway. The ACOP states that there should be gates which should be fitted with interlocking devices which prevent the opening of the gates other than when the lifting equipment is at the gate. The lifting equipment should not be able to be moved unless the gates are closed.

Marking of lifting equipment

Employers must make sure that machinery and accessories for lifting loads are clearly marked with their safe working loads. If the safe working load is dependent on configuration, then the safe working load for each configuration must be indicated and kept with the machinery.

Accessories for lifting must be clearly marked to show the characteristics required for their safe use. Lifting equipment must be marked to show whether or not it is suitable for the lifting of people. The ACOP states that where it is designed for the lifting of people, the maximum number of people to be carried must be indicated.

Organisation of lifting operations

Employers must make sure that every lifting operation involving lifting equipment is:

properly planned by a competent person;

appropriately supervised;

carried out in a safe manner.

This part of these Regulations is central to the safe use of lifting equipment. The ACOP and accompanying guidance gives extremely detailed descriptions of how to implement the proper planning, supervising and carrying out of lifting operations and should be studied carefully. It covers areas such as:

initial planning;

working under suspended loads;

visibility;

attaching/detaching and securing loads;

environment;

location;

overturning;

proximity hazards;

derating;

lifting of persons;

pre-use checks.

Thorough examination and inspection

Employers must make sure that before lifting equipment is used for the first time it is thoroughly examined for any defects unless it:

is new equipment that has not been used before and comes with a declaration of conformity made no more than 12 months previously;

has been received from another business and is accompanied by a copy of the report of a thorough examination.

Where safety depends on the installation conditions to make sure the lifting equipment has been installed correctly and is safe to use the equipment must be thoroughly examined after:

installation and before being used for the first time;

assembly and before being used in a new location.

Employers must make sure that lifting equipment which is likely to deteriorate in condition is thoroughly examined:

in the case of lifting equipment for lifting people or an accessory for lifting, at least every 6 months;

in the case of other lifting equipment, at least every 12 months;

in either case, in accordance with an examination scheme;

each time that exceptional circumstances occur which are likely to jeopardise the safety of the lifting equipment.

The ACOP gives further details on thorough examinations and states that the person carrying out a thorough examination must have such practical and theoretical knowledge of the lifting equipment as will enable them to detect defects or weaknesses and to assess their importance in relation to the safety and continued use of the lifting equipment.

The lifting equipment should be thoroughly examined at intervals no longer than those specified in these Regulations or in accordance with the intervals specified in the examination scheme for the equipment.

The examination scheme may be drawn up by the user, owner, manufacturer or some other independent party provided they have the necessary competence. The examination scheme drawn up by the competent person should identify and specify those parts of the lifting equipment which should be thoroughly examined.

The examination scheme should specify the intervals at which the lifting equipment should be thoroughly examined and, where appropriate, those parts that need to be tested.

Any examination scheme for lifting equipment should take account of:

its condition;

the environment in which it is to be used;

the number of lifting operations and the loads lifted.

If a risk assessment has identified a significant risk to the operator or other workers from the use of the lifting equipment, a suitable inspection should be carried out. The inspection should include, where appropriate, visual checks and functional tests.

Evidence of the last thorough examination or inspection must accompany every piece of lifting equipment, especially if it is obtained from another business or lent out to another business.

Reports and records

After thoroughly examining lifting equipment:

the employer must be notified of any defects in the lifting equipment, which are or could be a danger to people;

a written report must be made of the thorough examination containing the information specified in Schedule 1 and given to the employer or anyone from whom the equipment has been hired or leased;

where there is a defect in the lifting equipment likely to involve an imminent risk of serious injury a report must be sent to the relevant enforcing authority.

After inspecting lifting equipment employers must be notified of any defects which are or could be a danger to people, and as soon as practical a written record should be made of the inspection.

Employers who have been notified that the thorough examination of the lifting equipment has revealed a defect must make sure that the lifting equipment is not used until the defect has been remedied.

Circumstance and how long records must be kept

Lifting equipment other than an accessory never used before and accompanied by either a declaration of conformity or obtained from another business and accompanied by record of a thorough examination - For as long as the equipment is used

Lifting accessory never used before and accompanied by either a declaration of conformity or obtained from another business and accompanied by record of a thorough examination - For 2 years after the report is made

Lifting equipment dependent on the installation conditions- For as long as the equipment is used at that place

Lifting equipment subject to any other thorough examination - Until the next report is made or two years, whichever is later

Lifting equipment subject to an inspection - Until the next report is made

Declarations of conformity - For as long as the equipment is used

Exemption certificates

The Secretary of State for Defence may, in the interests of national security, issue an exemption certificate to any home or visiting armed forces.

Revocations and amendments

These Regulations revoke the:

Quarries (Ropeways and Vehicles) Regulations SI 1958/2110;

Shipbuilding (Particulars of Annealing) Order SI 1961/117;

Shipbuilding (Lifting Appliances, etc, Forms) Order SI 1961/431;

Construction (Lifting Operations) Regulations SI 1961/1581;

Construction (Lifting Operations) Reports Order SI 1962/225;

Construction (Lifting Operations) Prescribed Particulars Order SI 1962/226;

Hoists Exemption Order SI 1962/715;

Hoists Exemption (Amendment) Order SI 1967/759;

Offices, Shops and Railway Premises (Hoists and Lifts) Regulations SI 1968/849;

Offshore Installations (Operational Safety, Health and Welfare) Regulations SI 1976/1019;

Hoists and Lifts (Metrication) Regulations SI 1983/1579;

Construction (Metrication) Regulations SI 1984/1593;

Health and Safety (Miscellaneous Modifications) Regulations SI 1989/1141;

Lifting Plant and Equipment (Records of Test and Examination etc) Regulations SI 1992/195.

These Regulations amend the:

Mines and Quarries Act 1954;

Quarries (General) Regulations SI 1956/1780;

Shipbuilding and Ship-repairing Regulations SI 1960/1932;

Factories Act 1961;

Docks Regulations SI 1988/1655.

These Regulations have been amended by the:

Health and Safety (Miscellaneous Amendments) Regulations SI 2002/2174;

Supply of Machinery (Safety) (Amendment) Regulations SI 2005/831;

Construction (Design and Management) Regulations SI 2007/320;

Supply of Machinery (Safety) Regulations SI 2008/1597;

Health and Safety (Miscellaneous Repeals, Revocations and Amendments) Regulations SI 2013/448;

Mines Regulations SI 2014/3248;

Deregulation Act 2015 (Health and Safety at Work) (General Duties of Self-Employed Persons) (Consequential Amendments) Order SI 2015/1637;

Lifts Regulations SI 2016/1093;

Product Safety and Metrology etc. (Amendment etc.) (EU Exit) Regulations SI 2019/696.